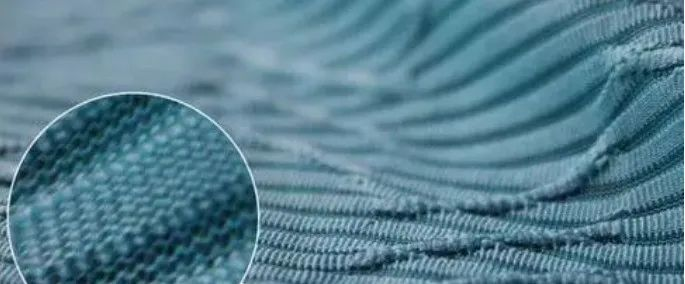

Spandex elastic knitted fabrics undergo large tensile deformation due to the tension during the weaving process. Although they have good resilience, they still cannot return to their natural state. The width and thickness of the fabric are easily unstable, which will have a greater impact on dyeing and finishing. The purpose of relaxation is to fully preshrink the fabric and eliminate the residual stress inside the fabric. In the dyeing and finishing processing of cotton knitted fabrics, the tension should be reduced as much as possible to keep the fabric in a relaxed state and avoid elongation of the fabric fibers. This article briefly discusses the matters that need attention during dyeing and finishing processing, common defects, analysis and prevention of dyeing and finishing wrinkles.

1.Precautions for the production of spandex elastic knitted fabrics during dyeing and finishing processing

1.Selection and inspection of gray fabrics

First check the width and warp and weft density of the incoming blank, and at the same time test the shrinkage elasticity of the gray cloth (take a whole piece of gray cloth, treat it with boiling water for 30 minutes, and test the elastic shrinkage after relaxation and drying, which is generally around 30%). For weft elastic fabrics, Then the width of the gray fabric should be adjusted proportionally according to the width of the finished product and the elastic elongation in the weft direction.

When accepting a production order, you must first understand the customer’s quality requirements, especially those related to elasticity, shrinkage, width and length. If the incoming blank is processed, it is necessary to understand the structural specifications, sizing slurry, warp and weft elastic elongation and shrinkage of the incoming blank, and detect the elastic expansion and contraction of the incoming blank; if the gap between the blank width and the finished product width is not greater than 20%, and If the elasticity of the gray fabric is above 30%, the weft elastic elongation and shrinkage effect of the finished product will be better.

Due to the different compactness of the fabric structure, the unbalanced left and right stress during weaving, and the incompatibility between the edge structure and the main structure of the fabric, the fabric is easily prone to curling during dyeing and finishing. Therefore, 2/1 and 3/1 twill The edge structure of satin fabric must be dense, and the longer the floating point, the wider and denser the edge organization is required.

2.Shrinking

In the dyeing and finishing process of spandex elastic fabrics, especially weft elastic fabrics, the tension applied to the weft yarns during weaving must first be eliminated in order to restore their due elasticity. Therefore, the shrinking process should be arranged at the beginning of pre-processing. This process can be arranged before singeing, with hot water pine pile washing or combined with desizing (the more complete the desizing, the more complete the shrinkage), and a loose open-width hot washing machine or jigger dyeing machine can be used. In order to prevent wrinkles and skirt curling caused by excessive shrinkage during high-temperature water washing, the step-by-step heating method (60, 70, 80, 90℃) should be used to gradually shrink the fabric.

3.Singeing

Before singeing, the seam head should be straight, and the width difference should be kept within the minimum range. Both ends of the fabric web should be hemmed to reduce edge removal, curling, and wrinkling in the subsequent processes. Spandex fabric is not resistant to high temperatures. During singeing, the process conditions of high speed and low flame temperature are generally used, and two forward and two reverse directions are used. It is important to note that the temperature of the fabric surface cannot be too high, otherwise the elasticity will be affected. It is required that the singeing is uniform, the cloth surface is clean, and there are no burn marks or wrinkles. After singeing, it is necessary to enter the next process as soon as possible. It is strictly forbidden to stack it for a long time.

4.Desizing

The key to the desizing effect is sufficient water washing and sufficient water volume. The method of gradually increasing the temperature step by step and reversing the flow step by step can be used to gradually shrink the fabric, and on the other hand, the slurry and impurities that have been swollen, oxidized and decomposed on the fabric can be quickly removed.

5.Pre-treatment and deboiling process

The spandex yarn of spandex weft elastic fabric cannot be used for a long time in hot and humid conditions, and is not suitable for rope processing; weft elastic fabrics (poplin gauze, Zhigon twill, etc.) and warp and weft double elastic fabrics are easily prone to curling during dyeing and finishing. It has wrinkled edges and is not resistant to concentrated alkali and high temperatures. It is also prone to wrinkles, curling and other defects during the stacking and steaming process. Therefore, the ideal process is to use cold rolling batch pre-treatment process conditions, and adopt low alkali concentration and normal temperature process conditions.

6.Pre-shaping and mercerizing processes

Pre-shaping and mercerization are key processes for stabilizing the shape of spandex elastic fabrics. The order of pre-shaping and mercerizing processes should be determined according to the actual situation. If the width of the semi-finished product is lower than the width of the finished product, it should be shaped first and then mercerized. When the width of the semi-finished product is higher than the width of the finished product, it should be mercerized first and then set.

7.Mercerizing

For mercerization of cotton and weft elastic fabrics, a straight-roller mercerizing machine should be used. Spandex yarn does not need to be mercerized, but the outer cotton fiber and warp yarn (cotton) need to be mercerized. Mercerizing not only stabilizes the weft dimension of the fabric, increases the dye uptake rate, and ensures the warp shrinkage, but also regulates elastic expansion and shrinkage. The temperature of the alkali tank should not be too high to prevent wrinkles, and is preferably 85 to 90°C. Since mercerization has no effect on modular nylon yarn, the main factor affecting the width is the shrinkage of spandex yarn. Therefore, through mercerization, the spandex/spandex fabric must obtain the previous elastic expansion and contraction, but the shrinkage cannot be exaggerated.

8.Shaping (pre-shaping)

Since the retraction rate of the spandex elastic fabric in the width direction is as high as 40% to 50% after the gray fabric is removed from the machine, the gray fabric becomes a highly elastic narrow-width fabric, which needs to be controlled by the shaping process to ensure that the fabric has the specified width and retraction. rate reaches equilibrium. In the shaping process, if the temperature is too high and the time is too long, the strength will be affected and it will easily turn yellow; if the temperature is too low and the time is insufficient, the effect will not be achieved. The width of the dropped fabric during setting directly affects the width of the finished product. The elasticity and retraction rate of the finished product can be predicted from the weft shrinkage rate after setting.

9.Finishing of spandex elastic fabric

When dyeing cotton/elastane elastic fabric, since the spandex yarn is wrapped in the cotton fiber and the content of spandex is only 3% to 5%, the dyeing process of pure cotton fabric can be used, generally using reactive and vat dyes. For medium and dark colors, the reactive dye two-phase process is mostly used. For elastic thin fabrics, if continuous pad dyeing is used, it is easy to wrinkle in the far-infrared drying and first pre-drying room, and when entering the reduction steamer. An expansion device can be added to the equipment to overcome this problem. There are also dyeing and printing methods that use steaming to fix the color. In order to prevent wrinkles during the dyeing process, infrared pre-baking and post-dyeing soaping are not performed.

When dyeing warp and weft double stretch fabrics, because they are prone to wrinkling and curling, they cannot pass through the continuous pad dyeing machine, so the cold pile dyeing process is chosen. Cold pile dyeing is rolled up immediately after padding the dyeing solution. Wrinkles will not be produced due to tension and other issues, and since the temperature does not rise during the dyeing process, it can effectively prevent elastic damage to the meridional elasticity caused by high temperature in the tight state. After dyeing Washed on a loose washing machine, so the warp and weft elasticity can be restored to its original state.

(1) Disperse dyes are suitable for dyeing under acidic conditions, and reactive dyes are suitable for dyeing under alkaline conditions.

(2) Disperse dyes are suitable for high-temperature dyeing, and reactive dyes exist in three types: low temperature, medium temperature, and high temperature.

(3) When dyeing with reactive dyes, a large amount of electrolytes must be added, and too much electrolytes will affect the stability of disperse dyes.

10. Finishing of spandex elastic fabric

In addition to meeting the requirements for the feel and appearance of the finished product, the finishing of elastic fabrics must also further reduce the width to the width of the finished product. Prevent shrinkage from occurring during placement, storage and transportation and after being wetted. In order to solve the problems of poor dimensional stability and high shrinkage of fabrics, post-finishing processes such as tentering and pre-shrinking are necessary.

When softening the tenter, you should use a softener that has little impact on the color, and its dosage should be properly controlled. Otherwise, the yarn will slip after partial stretching of the finished product, especially those with thinner warp and weft density in 4/1 and 3/1. Fabric. The hot air tenter should be equipped with an automatic weft straightening device to correct the arc weft skew in a timely manner. Before soft tenting, the dyed fabrics must be tested for warp and weft shrinkage and the skew standard test for twill fabrics. Based on the warp shrinkage of the width after shrinkage, the percentage of overfeeding and preshrinking on the tenter can be determined. The shrinkage rate of the machine and the size of the tenter; and the weft straightening device is adjusted according to the standard test results of the skew of the twill fabric. The width of the dropped cloth should be 2.5~5em (1~2 inches) wider than the finished product to ensure that the finished product width can be reached after pre-shrinking.

①Tentering process In the finishing process, the two processes of tentering and preshrinking are of great significance to control the dimensional stability and shrinkage of weft elastic fabrics. Since the fabric is subjected to warp tension after multiple processes, resulting in a large shrinkage, the finishing process must be determined based on the change in width during the pre-processing process. Special attention should be paid when finishing the tenter. If the fabric width is uneven and the elasticity is reduced, the temperature of the tenter should not be too high (not exceeding 160℃), the time should be <30S, and the cloth surface should not be dropped when the fabric is dropped. There must be a certain humidity (80% to 90% dry) to ensure that the width and shrinkage rate during pre-shrinking are within the required range.

②Control of tenter overfeeding In the soft tentering process, overfeeding must be carried out. If loose drying is followed by tight finishing and tentering, the warp stretch rate will be as high as more than 27%, which cannot meet the weft density requirements of the finished product. By using loose drying followed by overfeeding and finishing, the weft density requirements of the finished product can be fully met. In the finishing and tentering process, the fabric is padded with softener and dried in a short ring loosening method before being pinned. Because there is no tension, the needle clip cannot be used to detect the edge. It will also not work properly and will cause the clip to come off, so a certain amount of tension must be given to the entrance of the clip. But adding tension will cause the fabric to stretch. Therefore, overfeeding must be added to allow it to extend and then retract.

③Pre-shrinking When performing pre-shrinking, the width of the semi-finished product should be controlled to be consistent to prevent rubber blanket marks from uneven tension when feeding the fabric. Regarding the pre-shrunk size, the process parameters of the pre-shrunk machine should be adjusted based on the warp and weft shrinkage rate of the semi-finished product before pre-shrinking. The speed of pre-shrinking should be appropriately slowed down. The temperature should be high to solve the problem of shrinkage of the finished product. It can also play a certain role in shaping and stabilize the width. For fabrics that require skewing, it must be done after weft trimming. Twill fabrics should be skewed along the grain, and satin fabrics should be skewed against the grain.

2.Common defects of elastic knitted fabrics containing spandex

1.Elastic fabrics containing spandex are subject to a certain amount of tension during spinning, weaving, dyeing and finishing, which results in greater tension deformation and greater tension in the fabric, resulting in poor dimensional stability, large shrinkage, and difficult to control width.

2.Elastic fabrics containing spandex, especially weft elastic poplin, gauze, Zigong fabrics and warp and weft double elastic fabrics, are prone to wrinkles, curling and curling during dyeing and finishing.

3.After mercerization, the elasticity of cotton/ammonium elastic fabric is reduced, the shrinkage rate is increased, and the treatment effect cannot be achieved after setting.

4.During the dyeing and finishing of cotton/ammonia warp and weft dual-elastic fabrics, the warp elasticity is often damaged, color differences in the edges are prone to occur during dyeing,and the warp shrinkage is difficult to control.

5.During the processing of polyester/ammonia fine denier brushed elastic fabrics, the elasticity is reduced, the dyeing is stained, and the finished product feels bad and has indentations.

6.Cotton/nylon-nylon three-in-one elastic fabrics are prone to wrinkles and deformation during dyeing and finishing, while nylon dyeing is difficult, with low dye uptake and poor dye fastness.

7.Defects such as weft bias, wrinkles, and curling are prone to occur during the processing of cotton/polyester-span woven twill fabrics, and wrinkles are easy to occur during mercerization.

8.During the processing of nylon/cotton elastic weft fabrics, the edges of the fabric are severely curled, and the widths are different. The elastic dimensional stability of the finished.

3.Dyeing, finishing and prevention of wrinkles on spandex-containing elastic knitted fabrics

Wrinkles, that is, creases or chicken paw prints, have always been a difficult problem to solve in the dyeing and finishing of chemical fiber or cotton knitted fabrics, especially elastic knitted fabrics containing spandex. In view of the high elasticity and ductility of spandex itself, it is difficult to solve It is more likely to produce or form new wrinkles during processing. In severe cases, it is difficult to meet the requirements even after repairs, which will have a certain impact and loss on the product quality and efficiency of the factory.

Causes of wrinkles:

The main reason why ammonia-containing elastic knitted fabrics form wrinkles is that when the fabric in the cylinder is folded and squeezed when the temperature rises and falls too quickly,the fibers shrink unevenly in a short period of time, and the coils will shift and deform to form wrinkles;At the same time,during the processing and post-setting of the fabric after it comes out of the vat,if the temperature of the fabric itself is too high or the cooling is not enough, and the spandex shrinks before it rebounds,coupled with the long-term stacking pressure,it will also easily lead to wrinkles.

4.Measures to prevent wrinkles in spandex elastic knitted fabrics

1.Strengthen pre-treatment equipment and operations: Whether ammonia-containing elastic fabrics are refined in open width or rope shape, the synchronization between the equipment guide rollers must be strengthened or improved to prevent the fabric surface from being pulled and squeezed, and finally washed with room temperature water to prevent Wrinkles will occur if the temperature is overheated and the fabric is piled up too much, too high, or for too long.

2.Strictly control the pre-setting process: pre-setting can prevent curling, wrinkling and stabilize the door width. Without affecting the elasticity and feel of the spandex, a slightly higher temperature can be used for shaping, such as polyester and spandex, which can be controlled at 190-195°C. Nylon ammonia is 185-190℃, cotton ammonia is 180-185℃, and the vehicle speed is generally 15-20m. At the same time, keep the fabric surface smooth to prevent shrinkage and wrinkles.

3.During dyeing, adjust the nozzle pressure and the speed of the lifting roller: coordinate the two according to the weight of the fabric to prevent tangling, pressing the cylinder, and blocking the cloth. If necessary, increase the bath ratio appropriately to reduce the amount of cylinders and add anti-wrinkle in the bath agent or increase cloth speed, etc.

4.Control the heating and cooling speed: operate strictly according to the computer program settings, strengthen process discipline, control the temperature not to exceed 1-1.5°C/min, and prevent excessive speed from causing fiber aggregation and shrinkage to cause a large number of wrinkles.

5.Doing a good job in post-shaping can effectively reduce the dropping temperature, and appropriately raising the setting temperature can help eliminate wrinkles and slight wrinkles in the previous process. Generally, depending on the type, the controlled temperature of chemical fibers can be 10-20°C lower than the predetermined temperature, and that of cotton can be lowered by 20-30°C. At the same time, it is best to blow cold air and cool down the cooling roller at the cloth outlet to ensure that the cloth surface is below 50°C, otherwise the temperature will be lower than the predetermined temperature. Heat pressing can create new wrinkles.

6.In addition, if the unwinding loose cloth in the front line is left for too long, it will cause the spandex to shrink and form wrinkles on the edge of the fabric. It must be booked in time to avoid it. Including dehydration after dyeing, it must not be too dry. If it is left for too long, it is generally removed to 70%, and it should not be left for more than 2 -3 hours.

This article is reproduced from the Printing and dyeing news, for reference only.

Post time: Nov-06-2023