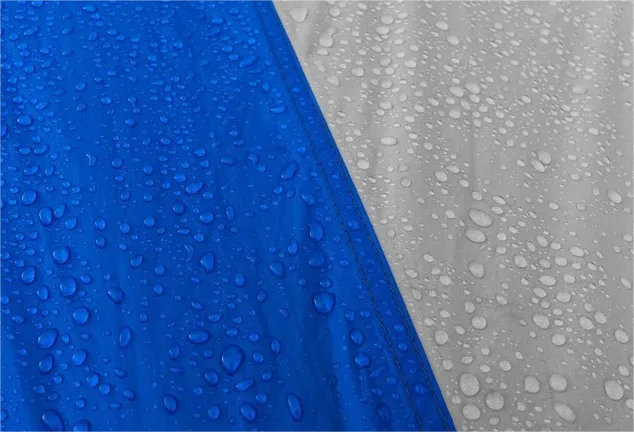

As we all know, the main use of tents is outdoor windshield and water resistance and cold. But do you know how the tent can do the wind and water and the cold, and it will not seep the water without being rained when it is windy and rainy? That is because the tent fabrics basically have functional effects such as waterproof and static water pressure.

1. Why do tents need to do waterproof

The tents on the market are generally based on nylon and polyester. Because the use environment of the tent itself is outdoors, the changes in outdoor weather are the biggest test of the tent, so it is necessary to have a better waterproof effect and considerable static water pressure in order to deal with the attack of light rain, heavy rain, and even heavy rain. If water is immersed, it will directly affect the people and items in the tent, so waterproof treatment is a necessary condition for the tent.

2. How to do a good job of waterproof treatment of tents

2.1, selection of textile fabrics

First of all, there are many varieties of textile fabrics and different characteristics. Different fabric characteristics and performance are also preferred. Therefore, choosing suitable fabrics is the first step in making tents waterproof. Generally speaking:

1. Polyester is thin and light, high in strength, good elasticity, wear resistance and corrosion, and is suitable for mountaineering and hiking wild camps.

2. Oxford is thick, but it is relatively heavy. It is suitable for large tents used in driving or small groups.

3. From the perspective of waterproof coating, although PVC (polyvinyl chloride) has good waterproof waterproof, it will be stiff and brittle in winter, which is prone to creases or breaks; PU (polyurethane) coating can not only overcome the defects of PVC, the waterproof effect It’s also good.

4. The material of the silver can be used to prevent ultraviolet rays. It is mainly used for leisure beach tents, shade tents, advertising tents, etc.

5. Some ultra -light accounts are more popular now. Different from the principles of waterproofing the PU layer of nylon and polyester fabrics. It uses silicon -coating (silicon resin) technology, which is much lighter in weight, but the price will be more expensive.

2.2, the choice of waterproofing agent

Generally speaking, most of the fabrics do not have waterproof function itself, and they must be organized later. One is to give it waterproof performance after waterproofing, and the second is that the coating treatment gives it waterproof performance. You can choose waterproof treatment agent specifically for tents. Select the processing methods such as soaking and soaking, so that the tent can achieve the effect of waterproof rain and rain. It can also be treated with waterproof coating. This treatment method can not only achieve waterproofing effects, but also get a more resistant water pressure effect than waterproof tidal agent.

Post time: May-06-2024