1.What is the network degree of silk?

The product of network processing is called network yarn,also known as intertwined yarn.It uses compressed air flow to spray,impact and collide the filament bundle,so that the individual filaments in the filament bundle are irregularly intertwined to form a good cohesion. Performance Knot Ribbon.

If pre-oriented yarn (POY) is processed through network,it can increase the cohesion between POY monofilaments,improve its post-processing performance,make it have better unwinding performance,and be less prone to lint and breakage during stretching and deformation.And loose loop silk etc.

When the drawn yarn and textured yarn are processed through the network,the processes such as doubling, twisting,and sizing can be omitted in the weaving process.The network yarn can be directly woven on the machine,and the breakage rate can be reduced and labor productivity can be improved10 % ~ 20%, the fabric has a certain wooly feel,is not easy to pill,and does not have the brightness of synthetic filaments.

2.How to measure network degree?

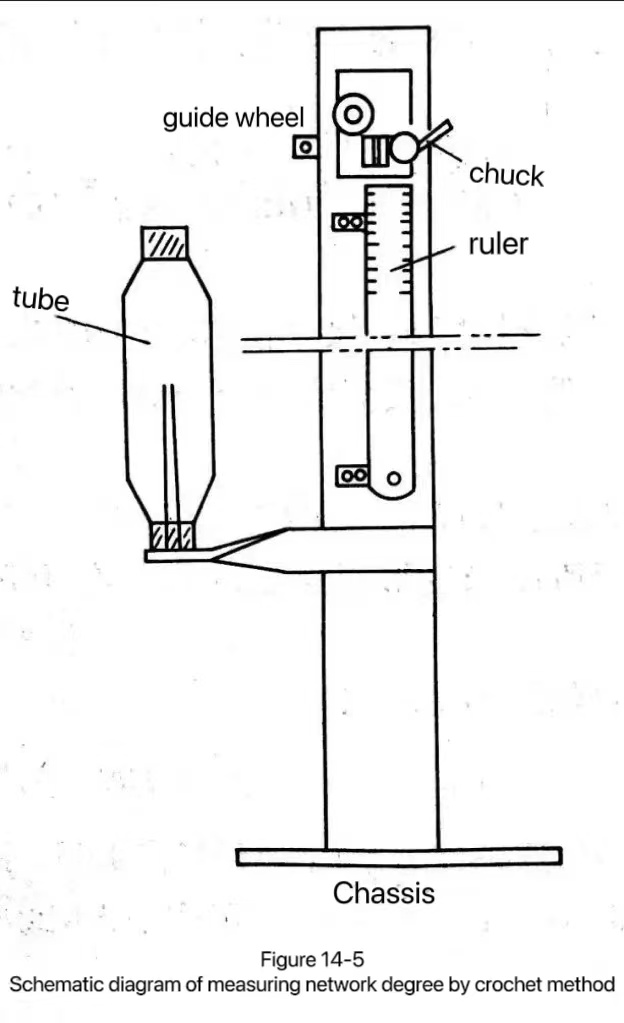

The measurement of network degree often uses the “needle method”,which is the most convenient.This method is the simplest.He uses small needles to insert into the network filaments for combing,thereby measuring the distance and distribution between the network points of the network filaments.The measuring device is shown in Figure 14-5.

When measuring,first insert the winding bobbin of the network filament into the bobbin holder of the measuring instrument,pull one end of the wire with your hand to withdraw the wire from the bobbin,pass it through the guide wheel,take a 1m sample, and clamp it with a chuck,hang a weight equivalent to 1/10 of the fiber fineness vertically from the lower end of the silk ribbon (if measuring 167dtex filament,hang a 16·7cN weight), and then insert a 4g thin steel needle into the upper end of the silk ribbon Inside the silk strip,roughly divide the silk strip into 2 bundles.

Hang a weight equivalent to 1/5 of the fineness at each end of the thin steel needle,make the steel needle fall at a speed of 2cm/s, and record the distance of the fall of the steel needle. Repeat the above test 50 to 100 times,find the average distance X of the steel needle falling 50 times or 100 times,and take its reciprocal to get the network degree.

3.Network degree of network silk

The measurement of network stability (network elimination rate, %) is to add a static load of 2.2cN/dtex to the lower end of the network filament measured by the network degree, leave it for 1 minute, remove the load, measure the network degree, and take the average of five times.

Calculate the network cancellation rate according to the following formula: Network cancellation rate (%) = (1-G/E) × 100

In the formula: E——the network degree before adding load; G——the network degree after adding 2.2cN/dtex load

4.The loop of network wire is stable

(1)Winding the silk skein:On a winching machine with a frame circumference of 1m, wind the silk skein with a pre-tension of 0.01cN/dtex so that the total fiber fineness is 2500dtex.

For example, when 167dtex filament is used to control the twist, the number of twist turns is calculated according to formula (11-7).

The number of turns of the silk strand = the total fineness of the silk strand (dtex)/the fineness of the silk sliver (dtex) * 2 = 2500 / (167 * 2) = 7.

(2)Measure the length a of the wire twist(a):Maintain the wire twist for 1 min under a load of 25cN (0.01cN/dtex), and measure a. The load value is calculated based on the total fineness of the undeformed raw silk strand, which is 0.5cN/dtex.

(3)Measure the length b of the wire twist(b):Maintain the wire twist under a load of 1250cN for 1 minute, and measure b. The load value is calculated based on the fineness of the undeformed raw silk strand, which is 0.5cN/dtex.

(4)Calculate the loop instability I1:I1(%)=(b-a)/a*100.

(5)Measure the length c of the strand:After measuring the length b of the strand, relax it for lmin, and then add a load of 25cN (0.0lcN/dtex). This load value is calculated based on the fineness of the undeformed raw silk strand. After lmin, measure the length c of the strand.

(6)Calculate the instability I2 of the wire loop:I2 (%) = c-a/a*100.

5.Boiling water shrinkage of air textured yarn

(1)Winding the silk skein:Wind the silk fabric under a pre-tension of 0.018cN/dtex, 1m per turn, 8 turns in total.

(2)Measure the length a of the skein:The load on the dry skein is the value of the total fineness of the undeformed original skein plus 0.018cN/dtex, and the length a is measured after 1 minute.

(3)Shrinking treatment:Shrink the strands in 95°C distilled water containing 1g/L Erkamtol Ba-Bager, an anionic active agent, for 15 minutes in a tension-free state.

(4)Shrinking treatment:Shrink the strands in 95°C distilled water containing 1g/L Erkamtol Ba-Bager, an anionic active agent, for 15 minutes in a tension-free state.

(5)Measure the length b of the strand:The load on the strand is the value of the total fineness of the undeformed raw silk plus 0.018cN/dtex, and the length b is measured after 1 minute.

(6)Calculate boiling water shrinkage:boiling water shrinkage (%) = a-b/b *100.

6.Height and density of air deformed wire loops

The deformation effect of air-textured yarn and its post-processing weaving performance and the feel and style of the fabric are related to the loop height and mesh density. Therefore, this is an extremely important indicator of air-textured yarn.

(1)Measurement of wire loop height:Since the wire mesh size is different, the distribution is uneven, and the discreteness is large, it is generally expressed by statistical values. The definition of DuPont in the United States is as follows:

Wire loop height = (maximum wire loop outer diameter – wire body diameter)/2

In actual measurement, since the probability of the wire loops being distributed along the surface of the wire strip is equal, the size of the wire loops can be known as long as the projection height of one side is measured with a projector. In this way, the testing efficiency can be doubled and the error can be reduced by half.

(2)Measurement of coil density:The coil height of air textured wire is low, while the density is high. At present, when using a domestic hairiness tester for measurement, the resolution cannot meet the requirements, resulting in significant errors. A projector can also be used for visual inspection. This is a method of measuring the projection number of air textured silk mesh on one side and then calculating it.

7.Network degree of air textured yarn

Network is a main feature of air deformation silk body, and the number of network points reflects the network effect.

Since the aggregation density, cohesion force, diameter, etc. of fibers in network points are different from those in non-nodes, the degree of network has a certain impact on the bending stiffness, density, bulkiness, evenness, and dyeing uniformity of air-textured yarns. , so the measurement of its network degree is very important.

Since the network density of air-textured yarn is high (more than 3 to 5 times higher than that of network yarn), and the length of network points cannot be ignored, the network degree of air-textured yarn is measured by measuring the number of complete network points per meter of yarn, and then taking the average Instead of using the distance between nodes divided by a fixed length to calculate the network degree like a network filament.

8.Diameter of air deformed wire

Thread diameter is an important parameter in fabric structure design, which is related to the thickness, stiffness, feel, etc. of the fabric. Photoelectric scanning method is used to measure diameter abroad. Since there is no such instrument in China, a projector is used to measure the diameter. However, since the cross-section of the air-deformed wire is approximately elliptical, a synchronous rotator can be added to the projector, so that the projection length of the major and minor axes of the ellipse can be measured, and then its equivalent diameter D can be calculated.

D=√ab where a and b are the projected lengths of the long and short axes respectively.

9.Dynamic instability

The stress experienced by the yarn during the weaving process or direct use changes within a certain range. Under this dynamic load, the structure of the yarn will undergo significant changes and cause irreversible deformation.

A simple device can be designed to push the beam to reciprocate up and down through the rotation of the cam, thereby measuring the elongation change rate of the wire under dynamic load, thereby expressing the dynamic instability S of the deformed wire.

S(%)=(L2-L1)/L1*100

In the formula: L1——initial length; L2——length after adding dynamic load

This article is reproduced from theTextile dry goods, for reference only.

Post time: Nov-13-2023