Principle of water repellent effect of lotus leaves

Over the past half century, many scientists have conducted in-depth research and experiments on the durable water-repellent effect of lotus leaves. Through scanning electron microscopy and atomic force microscopy observation of the leaf surface microstructure of more than 20,000 plants including lotus leaves, the reason why lotus leaves repel water was discovered.

The microstructure of the self-cleaning lotus leaf surface is actually a micron-nano hierarchical composite structure. The dual microstructure of the lotus leaf surface composed of the surface micron-level structure and the nanostructure formed by surface wax crystals provides the lotus leaf with It has a natural water-repellent barrier and has a good water-repellent effect.

At present, there are two main categories of methods at home and abroad to achieve durable water-repellent lotus effect on fabrics:

1) Simulate the rough structure of the lotus leaf surface through chemical modification, plasma modification, enzyme modification and other methods to form a lotus leaf effect on the fiber surface of the fabric, reducing its surface tension and forming a stable air layer, thereby making The fabric has long-lasting, durable water-repellent properties.

2) Use durable waterproofing agents to perform water-repellent finishing on the fabric to reduce the surface tension of the fabric and achieve the water-repellent effect of lotus leaves.

Application of durable waterproofing agent in durable water-repellent finishing of fabrics

The application of durable waterproofing agents is a widely researched and widely used durable water-repellent finishing method for fabrics.

This method uses the self-crosslinking of durable waterproofing agents and waterproofing materials to form a protective film with a surface tension lower than water on the surface of the fabric to prevent the fabric fibers from being wetted by water or water-based stains. Its process flow Mainly: padding durable waterproofing agent working fluid – drying – high temperature baking.

Waterproofing materials mainly include fluorine-free types (paraffin metal salts, quaternary ammonium compounds, resin derivatives, fatty acid chromium (aluminum), organic silicon) and organic fluorine types.

Organic fluorines dominate with their unique properties such as high surface activity, high thermal stability, high chemical stability, and water and oil repellency. However, organic fluorine chemicals can also cause ecological problems. Research has found that perfluorooctanoic acid, the main synthetic monomer of organic fluorine, is a substance that persists in the environment, has bioaccumulation and is potentially harmful to humans. Therefore, we are looking for environmentally friendly, non-toxic substances. Alternatives to fluorine and durable waterproofing agents have become a research and application trend in durable water-repellent processing of fabrics.

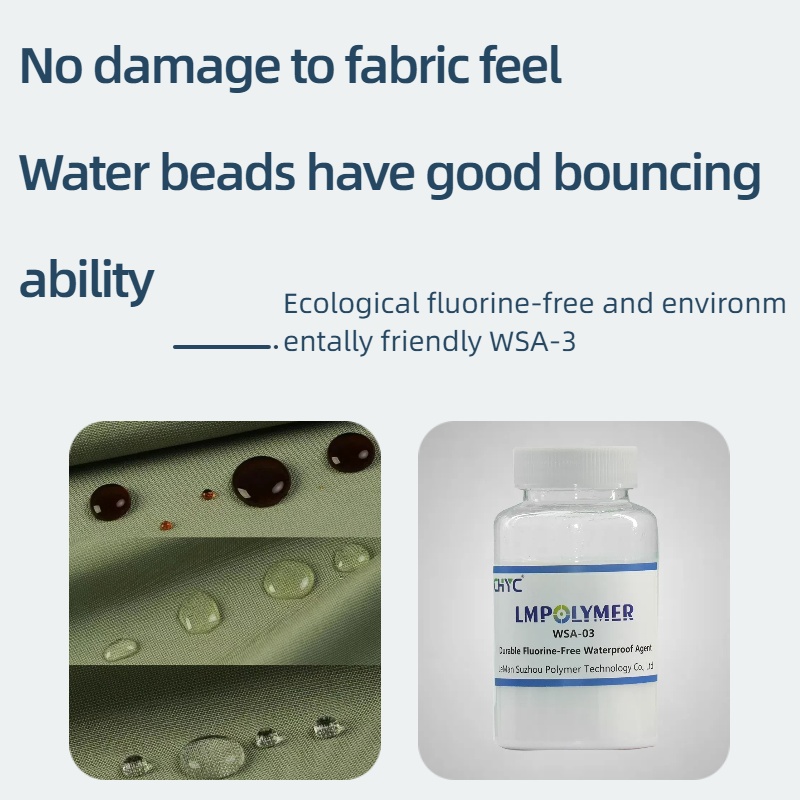

Currently, fluorine-free waterproofing agents on the market mainly include three categories: acrylic, polyurethane, and silicone. In order to meet the performance requirements of new fluorine-free waterproofing agents for stability, washability, and durability, Suzhou Leman Polymer Technology Co., Ltd. has launched CHYC durable fluorine-free waterproofing agent. Compared with traditional fluorine-free waterproofing agents, this fluorine-free waterproofing agent has excellent film-forming properties, wide versatility and more durable waterproofing effect. It has a better hand feel and the fabric High versatility.

The durable fluorine-free waterproofing agent WSA-03 can effectively improve the water-repellent properties of fabrics. After being washed multiple times, the finished fabrics can still maintain good water-repellent properties and have an obvious lotus leaf water-repellent effect. It has good processing stability, does not affect the fabric’s feel, appearance, and breathability. It has good water drop bounce and better hand scratches than similar products. It is especially good for use on cotton fabrics and spandex fabrics.

Suzhou Leman Polymer Technology Co., Ltd. focuses on the R&D and production of textile functional finishing agents. It has a senior R&D team and rich application experience. It can customize personalized functional finishing solutions according to fabric characteristics and development needs. For functional development consultation and technical exchanges on various textiles.

Please call: 17351128198 Email: info@lemanpolymer.cn

Post time: Dec-29-2023