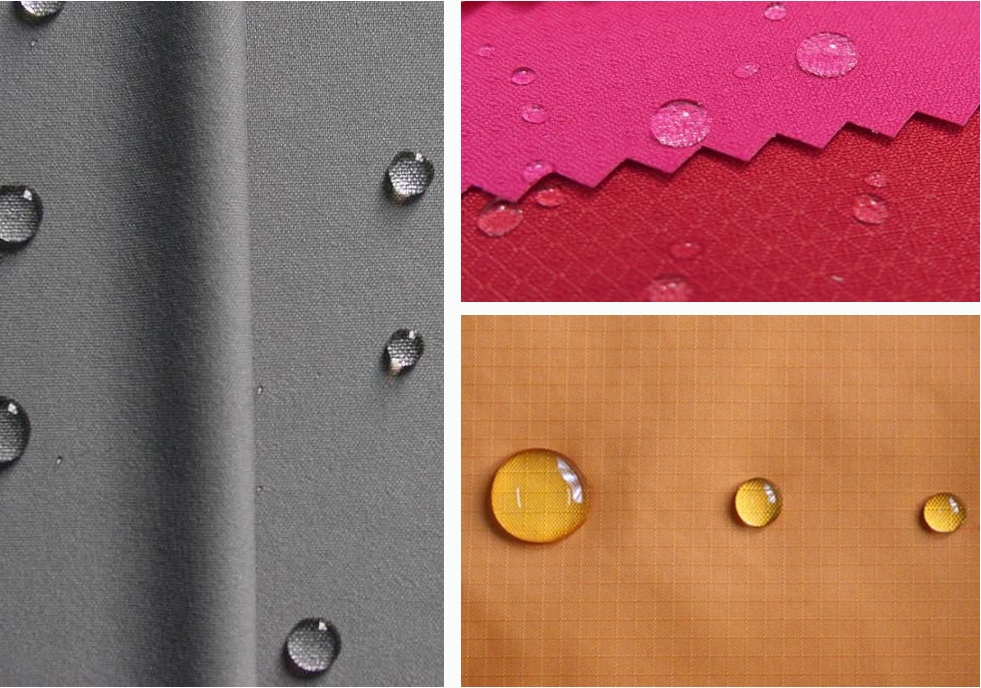

Under the barrier of environmental protection, the water repellent was gradually transformed from C8 to C6. According to statistics, about 13,000-15,000 tons of fluoride were consumed in the entire Chinese market in 2014, and C8 products accounted for 85%. Such a large amount also fully demonstrates the excellent waterproof and oil-proof effect of C8.

Now, under the restriction of relevant environmental protection standards, C8 products have been restricted to use in some modules, and replaced by C6. However, there is a concept that has long been implanted in everyone’s heart, that is: the waterproof effect of C6 is always inferior to that of C8.

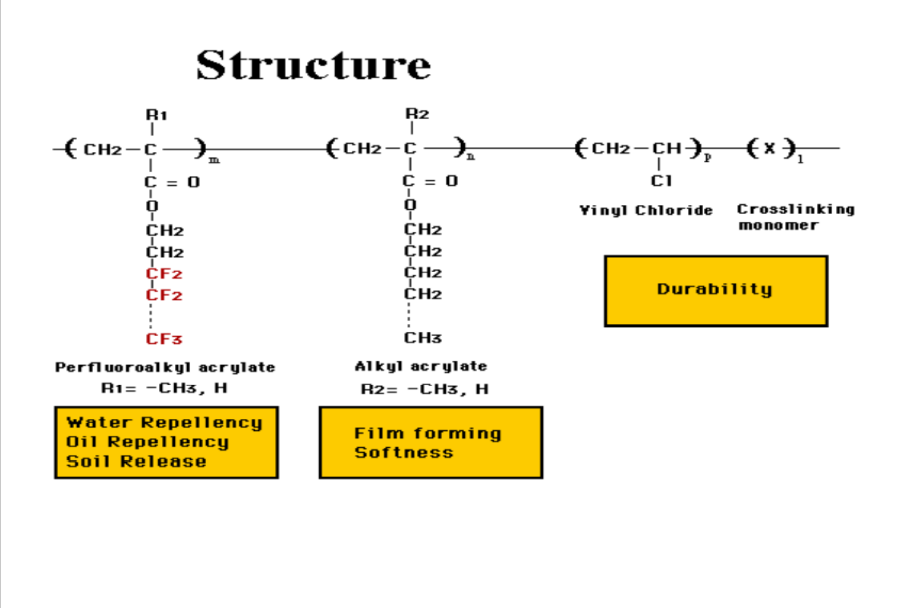

1. The problem of carbon chain length (ie fluoride content):

Fluorine is embedded in the carbon chain. If more fluorine is embedded, the carbon chain will become longer, and the carbon chain will be longer, then the stability between molecules will also be strengthened, and the stability will strengthen the ability to resist external stains and oil stains. Also enhanced.

2. The influence of the cleanliness of the cloth surface:

Regarding the impurities on the surface of the fabric, the impact on C6 will be higher than that of C8, and the cleanliness of the cloth surface should be determined before C6 is processed; C8 will also have requirements, but the requirements are not as high as those of C6. Therefore, the cleanliness of the cloth surface is very important for C6.

3. Effects with matching softener:

This is also related to the length of the carbon chain. The softener will have an impact on the waterproof effect, but the impact of C8 is less than that of C6.

Therefore, the product performance of C6 is indeed not as strong as that of C8 products. But considering environmental issues, we have to tend to use C6 products, and all we can do is to make C6 products have better performance as much as possible. Add some other auxiliaries when finishing, and slowly replace the C8 product.

Post time: Jun-27-2022