Water based high stain resistant finishing agent FL-L01 (bright light)

Characteristics:

Appearance: Milky white liquid

Solid content: 24 ± 1%

PH:6-8

Viscosity: 25 ° C ≤ 400CP

Baking temperature: 140 ° C~150 ° C

Significant features of the product:

Excellent anti staining and anti fouling performance

Can pass the wear resistance test (GB/T250)

Through the textile color fastness test (GB/T 250-2008)

Product process:

Sample usage and matching instructions:

Suggest using component A and component B in combination, shake well before use. The corresponding recommended basic formula and suggested processing techniques are as follows

Suggested basic formula:

Recommended formula for coating agent: 25G/A component+1G/B component. After preparing the surface coating according to the dosage, stir for 10-20 minutes to remove bubbles or follicles before use.

Suggested sample skin treatment process:

Leather sample → primer coating → drying → topcoat coating → baking → finished leather;

Coating: It is recommended to use a coating platform and a wire rod (40-60 microns wet film) to scrape the coating. The thickness can be adjusted appropriately

Baking: It is recommended to use a blast oven at 140 ℃~150 ℃/3 minutes. Before testing, it is recommended to test the temperature resistance of the leather. The process can be adjusted appropriately according to the actual situation;

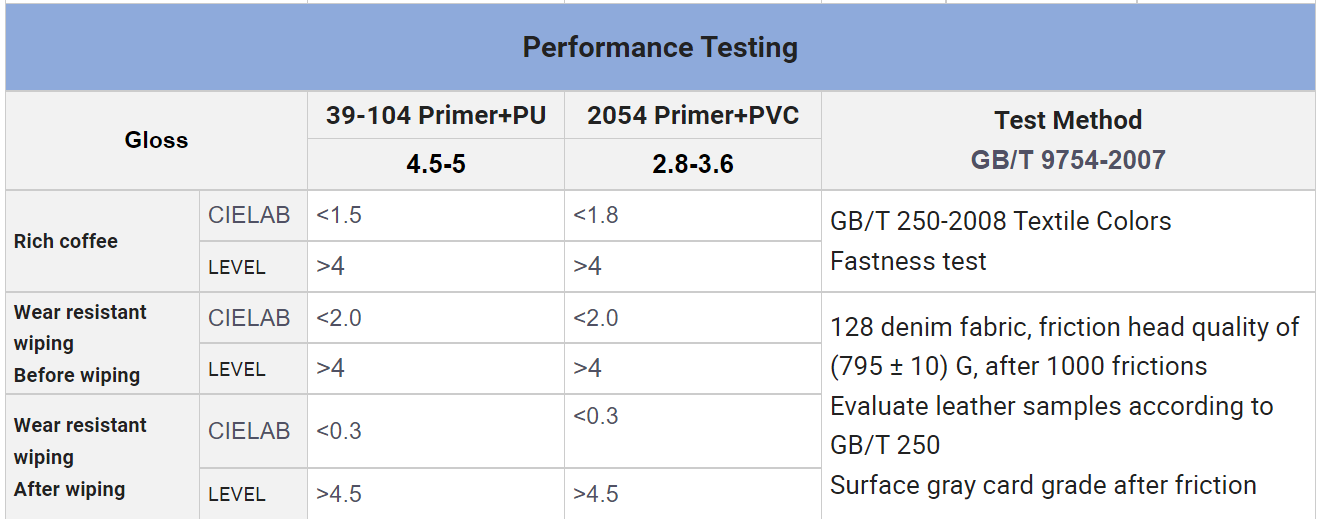

Product performance testing:

Storage method:

1.Before using it with other additives, the compatibility should be confirmed through preliminary tests.

2.The presence of hydrophilic substances remaining from previous processing on the processing cloth will affect the processing effect. Therefore, the cloth must be cleaned before waterproof and oil-proof processing.

3.Baking must be sufficient during processing, otherwise it will affect its performance.

4.Please use up the working fluid containing waterproofing agent and mixed chemicals within 12 hours. The stability and performance of the working fluid left for a long time must be confirmed before use.

5.Please use it as soon as possible after opening. Pay attention to sealing to prevent evaporation and avoid open flames and direct exposure to the sun.

6.Storage temperature is between 5℃~ 40℃ avoid freezing.

Artificial leather for car seats is stain resistant

Durable coating on the surface of light colored interior of automobiles

The surface of the car sunshade is stain resistant and wear-resistant

The stain resistance of artificial leather for light colored sofas

Anti fouling coating of artificial leather for chairs

Other furniture products of the same type, artificial leather

Light colored genuine leather bags and suitcases

Various types of bags and suitcases made of artificial leather

Shoes and clogs made of genuine leather or synthetic leather

FL-L01 is a dust-proof, anti fouling, anti staining, and scratch resistant coating. This coating can be added to leather and synthetic leather

A sturdy protective layer to prevent stains and fuel from entering the substrate material, making cleaning easier. It can also be used

To prevent daily damage and abrasions to seats, sofas, tables, chairs, leather surfaces, etc. caused by daily use.